Model 351 Pressure Transmitter

A flush diaphragm inhibits bacterial growth and facilitates Clean in Place (CIP) systems. The quick-disconnect Tri-clamp connections make these transmitters ideal for pharmaceutical, dairy and food processing applications where frequent cleaning is required.

Poptávkový systém

Nakonfigurujte si vlastní produkt, podle Vašich požadavků a potřeb. Pokud si s konfigurací nebudete jistí, uveďte do poznámek potřebné informace o stavajícím produktu třeba i konkurenčním. Rádi Vám pomůžeme najít alternativní produkt z řady Viatran. Pokud je Vaše poptávka urgentní informujte nás o tom, uděláme maximum, abychom Vám pomohli tuto situaci vyřešit co nejrychleji.

Pokud potřebujete více informací, neváhejte nás kontaktovat.

Viatran Configuration Code:

MODEL 351 PRESSURE TRANSMITTER

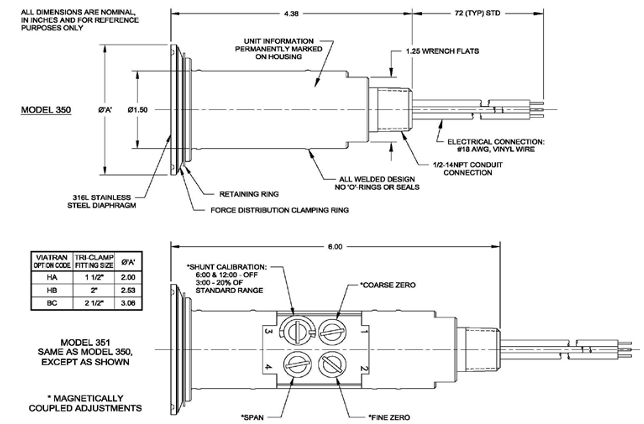

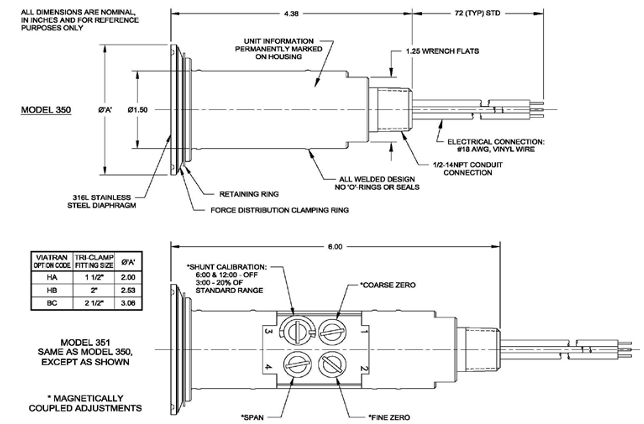

Flush Machined Sensing Diaphragm, External Adjustment, Tri-Clamp Fitting

Viatran technology allows for accurate pressure measurement up to 1000 PSI. The transmitter also has no moving parts, isolation diaphragm, or oil fill to contaminate your process fluid.A flush diaphragm inhibits bacterial growth and facilitates Clean in Place (CIP) systems. The quick-disconnect Tri-clamp connections make these transmitters ideal for pharmaceutical, dairy and food processing applications where frequent cleaning is required.

Viatran technology allows for accurate pressure measurement up to 1000 PSI. The transmitter also has no moving parts, isolation diaphragm, or oil fill to contaminate your process fluid.A flush diaphragm inhibits bacterial growth and facilitates Clean in Place (CIP) systems. The quick-disconnect Tri-clamp connections make these transmitters ideal for pharmaceutical, dairy and food processing applications where frequent cleaning is required.

Performance characteristics

| Full Scale Pressure Range |

0 - 100, 400, 1000 PSIS, PSIA |

| Combined Accuracy (Non-Linearity, Hysteresis, Repeatability) |

≤0.35% FSO |

| Full Scale Output (FSO) |

16 mA at 70°F (21°C) |

| Resolution |

Infinite |

| Long Term Stability |

≤±0.25% FSO per 6 months |

| Pressure Connection Effect Zero Balance |

≤±0.1% |

| Response Time (mechanical & electrical combined) |

≤50 mSec |

| Temperature Effect on Zero |

≤±2% FSO per 100°F (37°C) |

| Temperature Effect on Span |

≤±1% FSO per 100°F (37°C) |

| Temperature Effect on Calibrated Signal |

≤±1& FSO per 100°F (37°C) |

| Operating Temperature Range |

0°F to 180°F (-17°C to 82°C) |

| Process Temperature Range |

-65°F to 250°F (-53°C to 121°C) |

| Storage Temperature Limits |

-65°F to 250°F (-53°C to 121°C) |

Electrical characteristics

| Sensor Technology |

Bonded foil strain gage

|

| Supply Voltage |

12 to 30 Vdc |

| Power Supply Regulation |

≤±0.04% FSO per Volt |

| Output Signal |

4 - 20 mA at 70°F (21°C) |

| Load Impedance |

1925 Ohms max at 40 Vdc |

| Ripple |

≤±0.08% FSO |

| Zero Balance |

4 mA ±5% FSO at 70°F (21°C) |

| Zero adjustment |

4:1 turndown, externally 30 PSI min range |

| Range Calibration Signal |

20% of ±1.0% of FSPR, externally switched. Exact signal to pressure correlation is provided with each unit |

| Circuit Protection |

Varistor protected across the input leads for surges above 38 V and currents to 250 Amps peak with a pulse width of 8-20 µSecs. Reverse polarity protected |

| Bridge Resistance |

5000 Ohms nominal |

| Insulation Resistance |

≤100 MegOhms at 50 Vdc |

| RFI/EMI Suppression |

≤1% FSO output change at 30 V meter, 10-1000 mhz |

| Electrical Connection |

1/2” NPT male conduit, 3 wires, 18 AWG, 36” |

|

Color Wiring

|

Red +Power/Signal

Black -Power/Signal

Green Case Ground

|

Materials of Construction

| Enclosure Materials |

15-5, 304, and 316 stainless steel |

| Wetted Materials |

316 stainless steel |

| Identification |

.Laser etched onto bod |

| Measured Fluids |

Any gas or liquid compatible with 316 stainless steel |

Mechanical characteristics

| Pressure Connectio |

1 1/2”, 2”, 2 1/2” Tri-clamp |

| Proof Pressure |

1.5 times rated range |

| Burst Pressure |

≤3 times rated range or max orange of clamp and tubing, whichever is less |

| Weight |

30 oz |

Options

BZ

Mini change connector

DG

Improved temperature compensation

DH

Special range (350 only)

EA

Special calibration

TF

FM Intrinsic Safety

NH

Customer specified identification

PW

1/8 DIN digital indicator

ZP

CIA-C814-10-6P-10-0A1

Drawings

3A approved, Flush Machined Diaphragm Sensor, Tri-Clamp Fitting

Viatran technology allows for accurate pressure measurement up to 1000 PSI. The transmitter also has no moving parts,

isolation diaphragm, or oil fill to contaminate your process fluid.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety. More information

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety. More information

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results. More information

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results. More information

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support. More information

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support. More information

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support. More information

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support. More information

Viatran technology allows for accurate pressure measurement up to 1000 PSI. The transmitter also has no moving parts, isolation diaphragm, or oil fill to contaminate your process fluid.A flush diaphragm inhibits bacterial growth and facilitates Clean in Place (CIP) systems. The quick-disconnect Tri-clamp connections make these transmitters ideal for pharmaceutical, dairy and food processing applications where frequent cleaning is required.

Viatran technology allows for accurate pressure measurement up to 1000 PSI. The transmitter also has no moving parts, isolation diaphragm, or oil fill to contaminate your process fluid.A flush diaphragm inhibits bacterial growth and facilitates Clean in Place (CIP) systems. The quick-disconnect Tri-clamp connections make these transmitters ideal for pharmaceutical, dairy and food processing applications where frequent cleaning is required.