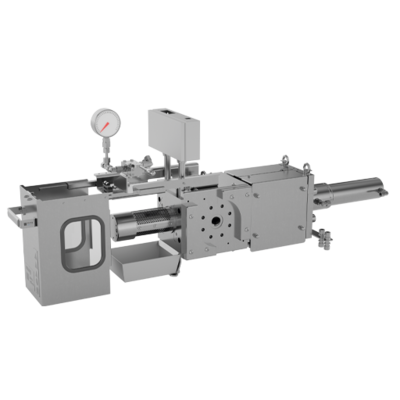

DSC - Single piston screen changer for extrusion and compounding applications

Discontinuous DSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration. Due to their constantly improved functionality continuous screen changers from Maag increase product quality significantly. DSC screen changers are based on the proven single-piston design that operates without any additional seals. Their sturdy construction available in all sizes and designs guarantees a reliable and leak-free filtration of polymer melts for many years.

Suitable for Masterbatch, Compounding, Recycling, Extrusion, Hot Melt Adhesives

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative MAAG products. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences.

If you need more information do not hesitate to contact us.

Configuration code

Options

Oil, liquid or steam-heated

High-pressure version up to 700 bar

High-temperature version up to 350 °C

Flow channels chromed, nickel-plated or special-coated

Stainless steel design

High-pressure breaker plate with max. 200 bar differential pressure (classic and PE version only)

Additional designs

Candle filters

Arched screens

Oval screens

Disk filters

Basket filters

Technical Data

Mounting: Compact mounting dimensions, all positions possible