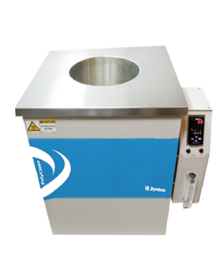

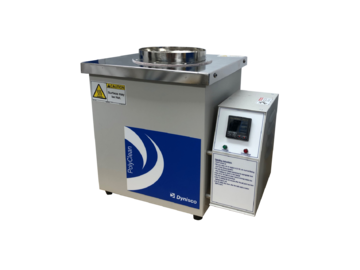

PolyClean 6"

Unlike other Fluidized baths, the Dynisco PolyClean 6L Fluidized bath has a smaller footprint, include advanced features and are safer than salt baths with thermal response that is 2 to 3 times faster than ovens. Unique bath cover and lid design that minimizes media loss. Media is either blocked by the lid or collected on the cover flange which then drops back into the system. The included lid with handle is lowered into the Fluidized Bath for cleaning parts, heattreating or calibrating temperature sensors as shown. An eyelet is added to the lid for suspending an optional basket for parts cleaning or deviceheat treatment.The optional probe support will suspend temperature sensors and thermometers into the Fluidized Bath for calibration. The probe holder immersion depth can be adjusted for added flexibility. Drill holes into the lid for the diameters you require.

Inquiry System

Configure your own device, according to your requirements and needs. If you are not sure about the configuration, make the necessary information about the processed materials in the notes. Thanks to this information, we are able to create several offers depending on the equipment and after the consultation, you can choose according to your needs. If you need a comparison for tenders, we will be happy to help you find an alternative product from Dynisco products.

If you need more information do not hesitate to contact us.

Configuration code

Dynisco PolyClean 6L Fluidized Temperature Bath

Features

■ Fully automate fluidizing air control

■ Compact working volume

■ Cover and lid design that minimize media loss

■ Independent over-temperature limit protection

■ Fast heat up

■ Small footprint for placement on standard lab benches

■ RS485 interface for PC connection & downloadble Windows software

■ Excellent stability, uniformity & accuracy

PolyClean Model 6L:

The PolyClean 6" Fluidized Temperature Bath can be used to clean small tooling from Laboratory Extruders ar lnjection molding machines, Capillary Rheometer and Melt Flow lndexer dies ar other small components used in polymer testing ar small part production. 5.3" X 6" Deep (134mm X 152mm)

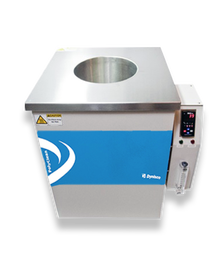

PolyClean Model 12L:

The PolyClean 12" The PolyClean 12" Fluidized Temperature Bath can be used to clean tooling from all extrusion, injection molding, blow molding, and laboratory applications. lts 12" deep ba sket is desig ned to handle a large variety of components from laboratory as well as production environments. The 12L can also be configured with its sensor support tray allowing (2) pressure sensors to be cleaned at a single time. 1 O" X 12" deep (8.4" diameter when using parts basket) and (213mm X 305mm)

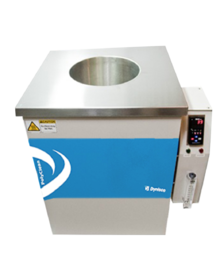

PolyClean Model 26L:

The PolyClean 26" The PolyClean 26" Fluidized Temperature Bath can be used to clean tooling from all extrusion, injection molding, blow molding, and laboratory applications. lts 26" deep basket is designed to handle a large variety of components from laboratory as well as production environments. 1 O" X 12" deep (8.4" diameter when using parts basket) and (213mm X 305mm)

Performance Characteristics

PolyClean Model 6L:

| Temperature Range |

50 to 605°C |

| Working Volume |

5.3” dia x 6” depth (134mm x 152mm) |

| Typical Stability thru Operating Range |

±0.3°C |

| Calibrated Accuracy |

±2.0°C |

| Heat up time to 600°C from ambient |

70 minutes |

| Cool down time: 600°C to 200°C |

130 minutes |

| Heater Power: 1 phase, 50/60 hz |

1920 watts |

| Air Pressure & Max Flow Required |

30 PSI, 1.8 CFM (2.1 bar, 50 lpm) |

| Overall Footprint H x W x D |

15”x17”x13” (381mm x 432mm x 330mm) |

| Total Unit Weight with Aluminum Oxide |

45 lbs (20kg) (unit only 32 lbs, 14.5kgs) |

Material Burn Off Temp Guide

• Nylon 450°C/842° F

• Paint 475-575°C/887-1067° F

• Styrene 450°C/842° F

• Polyethylene 425-450°C/797-842° F

• Polypropylene 425-500°C/797-932° F

• Flouropolymers 525°C/975° F

• PTFE 500°C/932° F

• PVC 460-540°C/860-1004° F

• High density polythene 450°C/842° F

• PEEK 500-525°C/932-977° F

• Silicone Rubber 535°C/995° F

• Polyesters 450°C/842° |

• Ethylene methacytic 450-480°C/842-8960F

• Polyurethane 440-450°C/824-842° F

• Polystyrene 450° C/842° F

• Rubber debonding 350°C/662° F

• Polycarbonate 400-425°C/752-797 ° F

• Organic matter oil/grease 300-5000C/572-932 ° F

• Crosslink PE 400°C/750° F |

The spacer cross into the PolyClean basket serves as a transfer and allows you to insert more parts and components for cleaning in one cycle. It is made of stainless steel and the robust design allows the use of up to 4 crosses (folds on top of each other). This allows you to use the entire length / depth of the basket.

Adapter for pressure sensors to the PolyClean system. It is used for cleaning pressure sensors. Adapter design protects the sensor from the radiant heat of the system. The side holes in the adapter serve to easily pour the alumina back into the polyClean system. The adapter includes locking rings for sensors, thanks to which it is possible to select the depth of immersion of the sensor tip.

The Dynisco PolyClean 12L Fluidized Temperature Bath can be used to clean extrusion tooling and all other types of hardware, shape set medical devices, calibration, testing various sensors and systems, heat treatment of metals as well as heating of reactors, coils, flasks and containers. Fluidized Temperature Baths typically provide faster processing times than ovens and furnaces and are much more thermally stable and uniform.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support.

The PolyClean 26" The PolyClean 26" Fluidized Temperature Bath can be used to clean tooling from all extrusion, injection molding, blow molding, and laboratory applications. lts 26" deep basket is designed to handle a large variety of components from laboratory as well as production environments. 1 O" X 12" deep (8.4" diameter when using parts basket) and (213mm X 305mm)

The PolyClean 26" The PolyClean 26" Fluidized Temperature Bath can be used to clean tooling from all extrusion, injection molding, blow molding, and laboratory applications. lts 26" deep basket is designed to handle a large variety of components from laboratory as well as production environments. 1 O" X 12" deep (8.4" diameter when using parts basket) and (213mm X 305mm)