MDA 410 | 412 | TDA 412 (NaK)

The MDA 410 series is the ideal choice for the food and pharmaceutical industries. The sensors are filled with mercury-free NaK (potassium sodium) and meet FDA and USDA requirements. The combination of NaK filling and Inconel membrane enables accurate pressure measurement in processes with temperatures up to 530°C. The sensors are characterized by their excellent repeatability and reliability. It is supplied with a connection to the 6-pin Bendix connector for easy handling. MDA 410 is the most used mercury-free pressure sensor with mV/V output signal. The version with temperature sensor can be found under the designation TDA 412.

PERFORMANCE CHARACTERISTICS

|

Pressure range:

|

0 - 35 bar to 0 - 700 bar

|

|

|

Accuracy:

|

± 0.5% of range (including linearity, repeatability and hysteresis)

|

|

|

Overload capacity:

|

2x pressure range for range 1000 and 1400 bar max. 1750 bar and max. 2400 bar for range 2000 bar

|

|

| Repeatability: | ±0.1% f.s.v | |

| Material in Contact with Media: | Inconel 718 | |

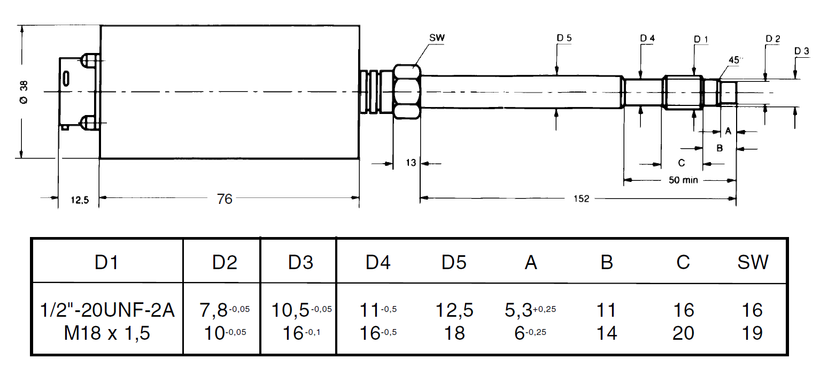

| Sensor connection: | 1/2 "-20 UNF-2A or M18 x 1.5 | |

| Mounting torque: | 25 Nm - 55 Nm | |

| Burst Pressure: | 6x pressure range max. 3000 bar | |

| Sensor construction: | MDA 410 - Sensor with rigid stem MDA 412 - Sensor with rigid stem and flexible stem TDA 412 - Combined sensor with rigid stem, flexible stem and built-in temperature sensor |

TEMPERATURE CHARACTERISTICS

|

Max. membrane temperature:

|

540°C

|

|

|

Zero shift (due to temperature):

|

< 0.4 bar/10ºC

|

|

|

-------------------------------------------

|

------------------------------------------------------------------

|

|

| Max. sensor body temperature: | 120°C | |

| Zero shift (due to temperature): | ±0.2% f.s.v./10ºC | |

| Shift sensitivity (due to temperature): | ±0.1% f.s.v./10ºC up to 50 bar ±0.2% f.s.v./10ºC |

ELECTRICAL CHARACTERISTICS

|

Supply Voltage:

|

10 Vdc - 12 Vdc

|

|

|

Output signal:

|

3.33 mV/V

|

|

|

Zero setting:

|

± 5% f.s.v. adjustable

|

|

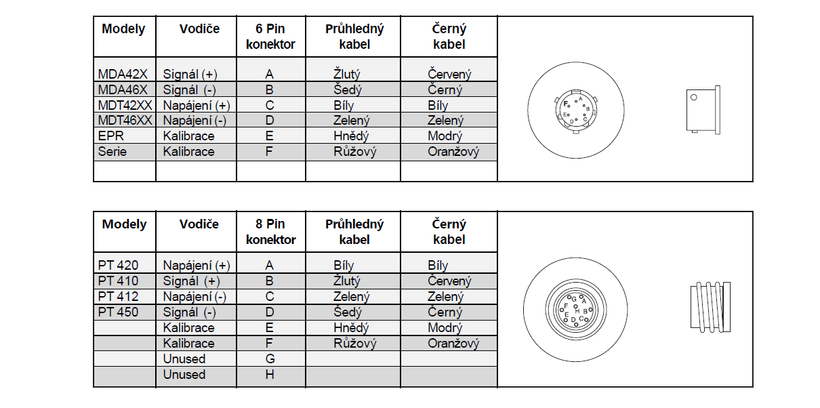

| Connector: | 6 Bendix PIN connector | |

| Leakage Resistance: | 1000 MΩ při 50Vdc | |

| Strain Resistance: | 350Ω | |

| Internal Shunt Calibration: | 80% f.s.v. ±0.5% |

SENSOR DIMENSIONS:

CONNECTOR WIRING DIAGRAM:

Certification Approval

|

EU Declaration of Conformity for Flush Mount mV/V Output |

|

ISO 9001:2015 |

|

EAC - The Eurasian Conformity mark |

|

GOST Approval |

|

RoHS Compliance Fact Sheet |