SPX-4 Series

The Dynisco SPX-4 Series is an intelligent pressure transmitter with a 4-20 mA output signal designed for use in hazardous, potentially explosive environments and is available with a variety of process and electrical connections.

These amplified transmitters eliminate the need for external signal conditioning. All models can be directly connected to high-level distributed control systems, PLCs, computers and similar control systems. With the possibility of optional functions such as temperature measurement using thermocouples or RTD.

PERFORMANCE CHARACTERISTICS

|

Pressure range:

|

from 17.5 bar up to 2000 bar

from 250 PSI up to 30 000 PSI from 1.75 MPa up to 200 MPa from 3.500 KPa up to 70 000 KPa

from 17.5 kg/cm2 up to 2000 kg/cm2 |

|

|

Accuracy:

|

4222

± 0.25% for pressure ranges >1,500 psi

± 0.50% for pressure ranges < 1,500 psi 4232

± 0.25% for pressure ranges >1,500 psi;

± 0.50% for pressure ranges < 1,500 psi

4352

± 0.25% for pressure ranges > 1,500 psi;

± 0.50% for pressure ranges < 1,500 psi

4502 ± 0.50%

4622 ± 0.50% 4672 ± 0.50% |

|

|

Overload capacity:

|

2X FSO or 35,000 psi,

which is less than 1.2 X FSO 35,000 - 72,500 psi

|

|

| Repeatability: | 0.1 % f.s.v | |

| Material in Contact with Media: | DyMax coating 15-5 PH SST | |

| Sensor connection: | 1/2"-20 UNF , M18 x 1.5 | |

| Mounting torque: |

4222: 500 inch-lbf max |

|

| Sensor construction: | according to the configuration |

TEMPERATURE CHARACTERISTICS

|

Max. membrane temperature:

|

(400°C) max [model SPX4502 limitován do 315°C ]

|

|

|

Zero shift (due to temperature):

|

4222: 27 psi/100°C typical

4232: 27 psi/100°C typical

4352: 27 psi/100°C typical

4502: 1 psi/100°F (od 75-450°F); 2 psi/100°F (od 450-600°F) 4622: 45 psi/100°C typical

4672: 45 psi/100°C typical |

|

|

-------------------------------------------

|

------------------------------------------------------------------

|

|

| Max. sensor body temperature: | 85°C | |

| Zero shift (due to temperature): |

4222: 0.02% F.S./°C max |

|

| Shift sensitivity (due to temperature): |

4222: 0.02% F.S./°C max |

ELECTRICAL CHARACTERISTICS

|

Supply Voltage:

|

16 - 36 Vdc (Standard); 16 - 30 Vdc (ATEX IS)

|

|

|

Output signal:

|

4 - 20 mA with optional HART ™

|

|

|

Zero setting:

|

-

|

|

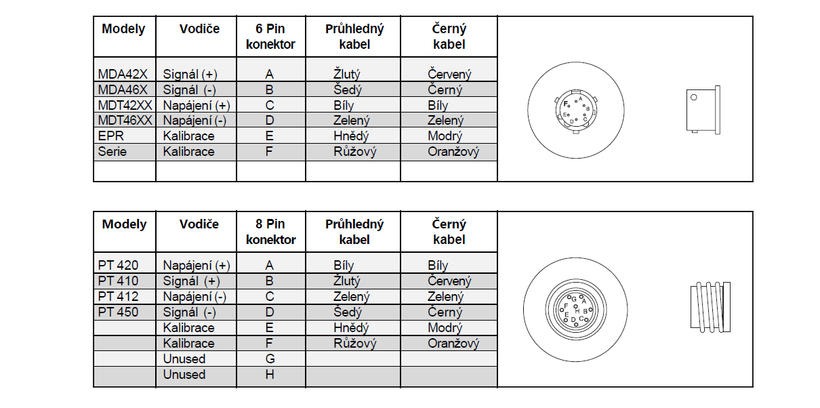

| Connector: | 6 Bendix PIN connector | |

| Leakage Resistance: | 500 Ω @ 24 Vdc, 1,000 Ω @ 36 Vdc | |

| Internal Shunt Calibration: | 80% f.s.v ± 0.50% f.s.v |

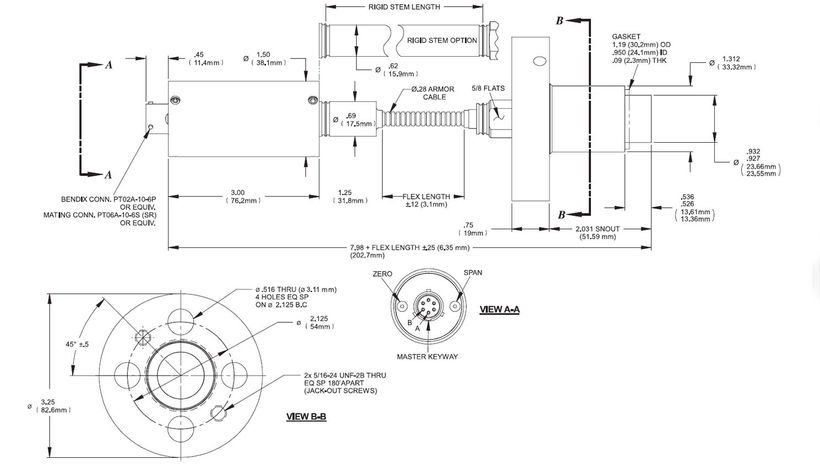

SENSOR DIMENSIONS:

CONNECTOR WIRING DIAGRAM:

Certification & Approval

|

|

EU Declaration of Conformity |

|

|

ISO 9001:2015 |

|

|

EAC - The Eurasian Conformity mark |

|

|

GOST Approval |

|

|

RoHS Compliance Fact Sheet |

|

|

Safety Integrity Level - SIL2 |

|

|

Canada CSA Explosionproof Approval SPX2 & 5 Series |

|

|

KTL IS Approval SPX |

|

|

NEPSI Approval: SPX 2 Series |

|

|

Explosion Protection Certificate of Conformity |

|

|

US FM Explosionproof Approval SPX2 & 5 Series |