SPX-T - 3 Series

TSPX-T (Series 3) is an intelligent 4-20 mA series of sensors that includes temperature compensation and Dynisco Innovation - DynaLarity ™. The SPX-T delivers the most powerful sensors in the range. Temperature compensation is based on RTD measurements that compensate for temperature changes that reduce temperature variations and increase accuracy. There is no need to perform a temperature calibration after installing the sensor.

DynaLarity uses an advanced algorithm that will linearize offsets on the sensor. The combined temperature compensation and DynaLarity functions reduce temperature-related deviations by up to 80% and improve accuracy by more than 60% compared to other sensors. Combined temperature sensors are also available (RTD or 4-20mA). HART communication is a standard in this series. SPX 3 series with welded non-removable construction designed for use in potentially explosive atmospheres and other demanding applications.

These amplified transmitters eliminate the need for external signal conditioning. All models can be directly connected to high-level distributed control systems, PLCs, computers, and similar control systems.

PERFORMANCE CHARACTERISTICS

|

Pressure range:

|

from 35 bar up to 700 bar

from 500 bar up to10 000 PSI from 3.5 MPa up to70 MPa from 3.500 KPa up to70 000 KPa

from 35 kg/cm2 up to700 kg/cm2

|

|

|

Accuracy:

|

32xx:

± 0.25% for pressure range > 3,000 psi

± 0.5% for pressure range = 1,500 psi

± 0.75% for pressure range < 1,500 psi

33xx:

± 0.15% for pressure range > 3,000 psi

± 0.25% for pressure range = 1,500 psi ± 0.5% for pressure range < 1,500 psi |

|

|

Overload capacity:

|

1.5 x f.s.v

|

|

| Repeatability: | 0.1 % f.s.v | |

| Material in Contact with Media: | 15-5 PH SST DyMax coating | |

| Sensor connection: | 1/2"-20 UNF , M18 x 1.5 | |

|

Mounting torque: |

3242: 500 inch-lbf max |

|

| Sensor construction: | according to the configuration |

TEMPERATURE CHARACTERISTICS

|

Max. membrane temperature:

|

400°C max

|

|

|

Zero shift (due to temperature):

|

-

|

|

|

-------------------------------------------

|

------------------------------------------------------------------

|

|

| Max. sensor body temperature: | 85°C | |

| Zero shift (due to temperature): | - | |

| Shift sensitivity (due to temperature): | - |

ELECTRICAL CHARACTERISTICS

|

Supply Voltage:

|

16 - 36 Vdc (Standard); 16 - 30 Vdc (ATEX IS)

|

|

|

Output signal:

|

4 - 20 mA with optional HART ™

|

|

|

Zero setting:

|

-

|

|

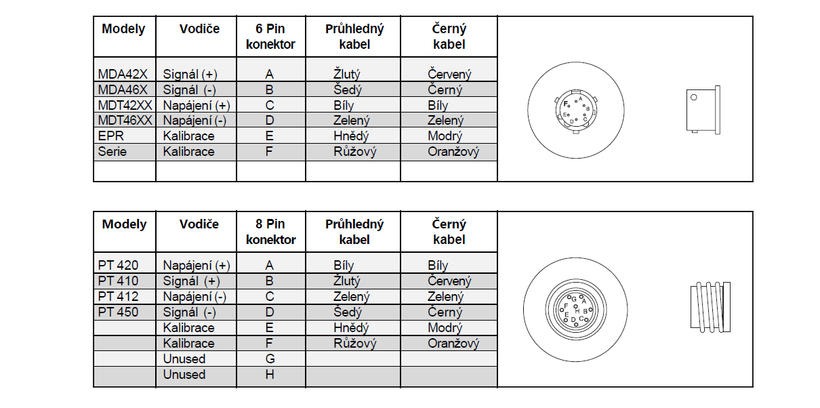

| Connector: | 6 Bendix PIN connector | |

| Leakage Resistance: | 500 Ω @ 24 Vdc, 1,000 Ω @ 36 Vdc | |

| Internal Shunt Calibration: | 80% f.s.v ± 0.50% f.s.v |

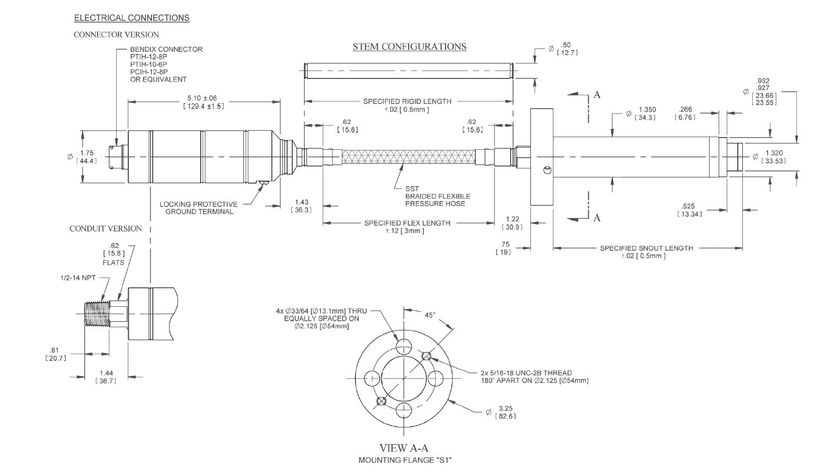

SENSOR DIMENSIONS:

CONNECTOR CONNECTION:

Certification & Approval

|

|

EU Declaration of Conformity |

|

|

ISO 9001:2015 |

|

|

EAC - The Eurasian Conformity mark |

|

|

GOST Approval |

|

|

RoHS Compliance Fact Sheet |

|

|

Safety Integrity Level - SIL2 |

|

|

Canada CSA Explosionproof Approval SPX2 & 5 Series |

|

|

KTL IS Approval SPX |

|

|

NEPSI Approval: SPX 2 Series |

|

|

Explosion Protection Certificate of Conformity |

|

|

US FM Explosionproof Approval SPX2 & 5 Series |