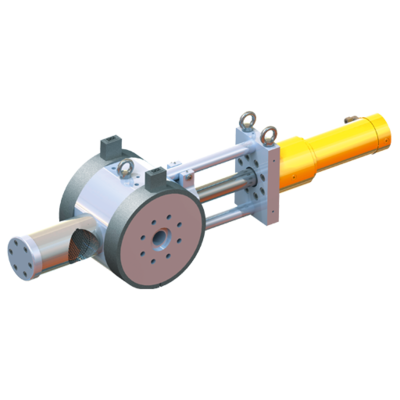

SSC

The compact single-piston screen changers SSC from MAAG provide a cost-effective filtration alternative for extrusion applications which allow for interruptions in the melt stream during screen changeovers. SSC operate without any additional seal. Their sturdy construction guarantees reliable and leak-free filtration of polymer melts. The rheologically optimized flow channel directs the melt flow optimally and with a short residence time into the screen cavity. The breaker plate is fitted with screen mesh suitable for the required filtration size. The screen changer is operated by a hydraulic piston.

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative MAAG products. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences.

If you need more information do not hesitate to contact us.

MAAG Configuration code

TECHNICAL DATA

| Throughput rate [kg/h] | 40 – 1700 | |

| Operation method | diskontinuierlich | |

| Required heating output [kw] | 1,7 – 7,2 | |

| Additional designs |

Candle filter elements |

|

| Filter surface [cm²] | 7 – 314 | |

| Number of sieve cavities | 1 | |

| Screen diameter/length | 30 mm to 200 mm | |

| Filtration area | 7 cm2 to 314 cm2 | |

| Mounting | Compact mounting dimensions, all positions possible | |

| Technology | Proven sealless single-piston desig |

APPLICATION FIELDS

|

Flat films

|

|

|

Foam films

|

|

|

Blown films

|

|

| Plates | |

| Pipes | |

| Profiles | |

| Blown mouldings | |

| Fibres | |

| Granulation | |

| Compounding |

OPTIONS

|

Choated flow channels

|

|

|

Stainless steel design

|

ACCESSORIES

|

Connection adapter

|

|

|

Support carriages

|

|

|

Control systems

|

|

| Breaker Plates | |

| Protective devices |