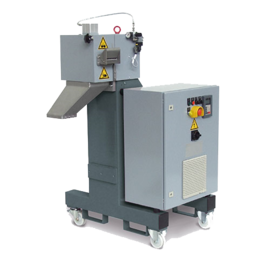

PRIMO 60/120 E

Successfully applied by hundreds of customers, the proven WSG dry-cut strand pelletizing systems with PRIMO E pelletizers produce the highest quality of cylindrical pellets or microgranular compounds that are ideal for further processing for strand pelletizing and dry cut pelletizing systems. Variable system configurations allow for optimal matching with your specific production requirements and also provide utmost flexibility for product changeovers.

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative MAAG products. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences.

If you need more information do not hesitate to contact us.

MAAG Configuration code

TECHNICAL DATA

| PRIMO 60 E | PRIMO 120 E | |||

| Operating width: | 60 mm | 120 mm | ||

| Drive system: | AC motor with belt drive | AC motor with belt drive | ||

| Motor power of pelletize: | 2,2 kW | 4,0 kW | ||

| Line speed at pellet length of 3 mm: | 20-90 m/min | 20-90 m/min | ||

| No. of strands at a 75 % utilization rate and a pellet diameter of 3 mm: | 10 | 16 | ||

| Throughput rates | ||||

| Product: | Density [g/cm3] |

PRIMO 60 E |

PRIMO 120 E |

|

| PP, PE: | 0,91 | 350 | 750 | |

| GPPS, SAN: | 1,04 | 400 | 750 | |

| ABS, HIPS: | 1,04 | 400 | 750 | |

| PMMA: | 1,18 | 450 | 750 | |

| PET, PBT: | 1,31 | 500 | 600 | |

| PA 6, PA 6.6: | 1,14 | 425 | 510 | |

| PET, PBT, PA, PP + 15 bis 50 % glass fi ber: | 1,00 | 375 | 375 | |

| 1,55 | 500 | 500 | ||

| Thermoplastic elastomers: | 1,30 | 425 | 750 | |

| Masterbatch from 40% of the fulfillment level: | 1,30 | 500 | 750 | |

| * Pellet length 3 mm, pellet diameter 3 mm, and maximum number of strands | ||||