Model RM570 Pressure Transmitter

All welded construction and stainless steel surfaces makes the RM570 ideal for harsh environments. Viatran's rugged pressure transmitters are designed to withstand heat, vibration, pressure spikes and EMI/RFI caused by the the surrounding equipment.

All Viatran Rolling Mill units are built and configured to order with a choice of four pressure ranges,ensuring you have the best solution for your application.

Inquiry system

Configure your own product according to your requirements and needs. If you are unsure of the configuration, provide us in the notes the necessary information about the existing sensor or product, even a competitor. We will be happy to help you find an alternative Viatran product. If your request is urgent, let us know. We will do our best to help you resolve this situation to your satisfaction as quickly as possible. If we have all the information, we are able to offer a model with minor differences, which is in stock and you can have another product available the next day.

If you need more information do not hesitate to contact us.

Viatran Configuration Code:

MODEL RM570 PRESSURE TRANSMITTER

4-20 mA, 0-100 Bar thru 0-350 Bar

RM 570 transmitters provide a rugged, sealed solution for the harsh industrial environments found in Rolling Mills and the metals industry.

All welded construction and stainless steel surfaces makes the RM570 ideal for harsh environments. Viatran's rugged pressure transmitters are designed to withstand heat, vibration, pressure spikes and EMI/RFI caused by the the surrounding equipment.

All Viatran Rolling Mill units are built and configured to order with a choice of four pressure ranges,ensuring you have the best solution for your application.

Performance characteristics

| Full Scale Pressure Ranges |

0-100 Bar (0-1450 psi)

0-150 Bar (0-2175 psi)

0-250 Bar (0-3625 psi)

0-350 Bar (0-5076 psi) |

| Static Error Band |

≤±0.25% FSO typical(Includes BFSL, Hysteresis and Repeatability by RSS)

|

| Full Scale Output (FSO) |

4-20 mA (16 mA FSO)

|

| Zero and Span Balance |

±1% FSO |

| Response Time |

<2 mSec to reach 90% FSO |

| Full Scale Output (FSO) |

16 mA |

| Zero and Span Balance |

±1% FSO |

| Long Term Stability |

≤±0.25% FSO per 6 months |

| Response Time |

<2 mSec to reach 90% FSO |

| Temperature Effect on Zero |

≤±1% FSO per 100°F (37°C) |

| Temperature Effect on Span |

≤±1% FSO per 100°F (37°C) |

| Compensated Temperature |

70°F to 170°F (21°C to 76°C) |

| Operating Temperature |

-40°F to 190°F (-40°C to 87°C) |

| Storage Temperature Limit |

-65°F to 250°F (-53°C to 121°C) |

Electrical characteristics

| Supply Voltage |

12 to 30 Vdc |

| Power Supply Regulation |

≤±0.02% FSO per Volt |

| Output Signal |

4 - 20 mA |

| Bridge Impedance |

5000 Ohms nominal |

| Circuit Protection |

Varistor protected across the input leads for surges above 40 V and currents to 250 Amps peak with a pulse width of 20 μSecs. Reverse polarity protected. |

| Insulation Resistance |

>200 MegOhms to case ground |

| Electrical Connections |

1/2" NPT (M), 18 AWG wire, 72" |

| Pin Outs |

Wire Color Codes

Red

+Power/Signal

Black

-Power/Signal

Green

Case ground

White

No Connection

|

| Connector Options |

BP Micro change (M12)

BN 4-pin bayonet

ZU Cable gland |

Materials of Construction

| Enclosure |

0-100 thru 0-15K PSI15-5 PH and 316 stainless steel (0-6.8 thru 0-1034 bar)

0-20K thru 0-100K PSI316 SST and PH 13-8 Mo SST (0-1378 thru 0-6894 bar)

|

| Wetted Parts |

0-100 thru 0-15K PSI15-5 PH stainless steel (0-6.8 thru 0-1034 bar)

0-20K thru 0-100K PSIPH 13-8 Mo SST (0-1378 thru 0-6904 bar)

|

| Shock Limitation |

100 G’s |

| Weights |

24 oz. (0.680 kilograms) |

| Identification |

Laser etched onto body |

| Enclosure |

Classification NEMA 4X |

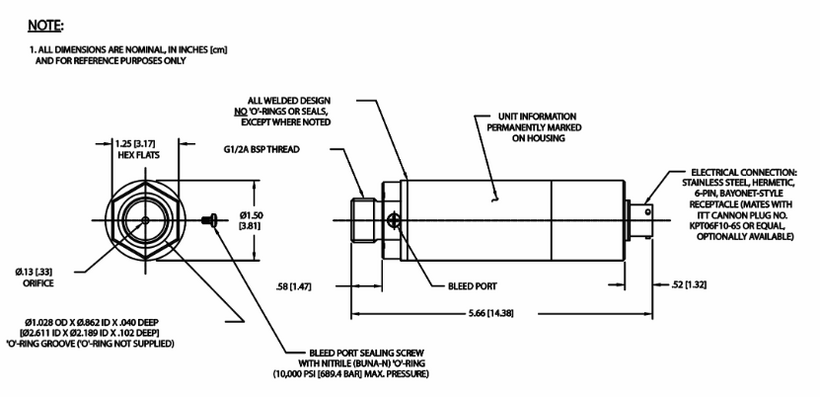

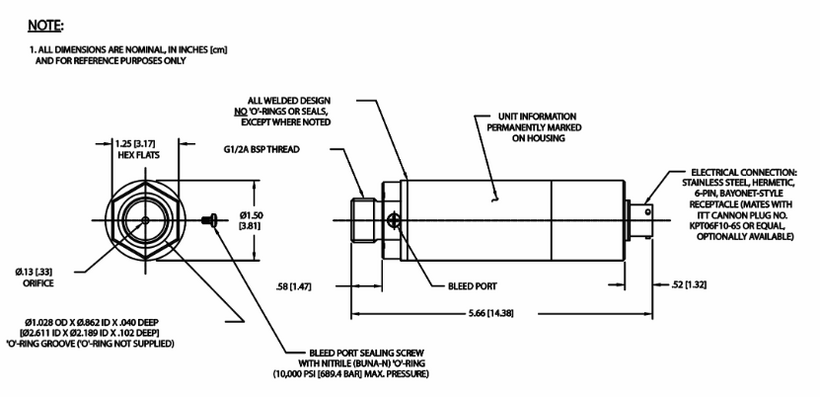

Mechanical characteristics

| Pressure Connection |

G 1/2A BSP(M) with Bleed Port*

G 1/2A BSP(M) without Bleed Port

G 1/4B BSP(M) without Bleed Port |

| Proof Pressure |

Up to 4 times FSPR(1378 Bar* (20,000 psi),whichever is less)

|

| Burst Pressure |

≥ 6 to 10 times FSPR dependent on sensor, consult engineering for details

|

| Mounting |

Supported by process piping or optional mounting bracket |

Options

B ( )

Alternate Electrical Connections**

DF

Bleed port (10K PSI and below)

EA

Special calibration run

NH

Customer specified identification

NJ

CE Marking

Y ( )

Alternate pressure ports

ZU

Direct Coupled Cable**

Note:

Application of some available options may affect standard performance. Consult your Viatran Representative for details.

* For safety purposes, Viatran will only proof pressure in production to 700 Bar (10.000 psi) for units with Bleed Ports.

** Custom wiring / pin outs avilable for your application.

Drawings

0-5 VDC, High Accuracy, 3 thru 5000 psi

Viatran's Model 245 DigiComp pressure sensor is among our most accurate pressure transmitters for industrial test and research applications. The 245 measures gage and absolute pressure from 3 PSI to 5,000 PSI (0.2 to 345 bar) with standard accuracy of ≤±0.06% FSO.

0-7500 thru 100K psi, 0-5Vdc output, 0.15% accuracy

Viatran's Model 245 High Range pressure sensor is among our most accurate pressure transmitters for industrial test and research applications at higher pressures. Improved accuracies are available, as well as improved temperature performance.

4-20 mA output, High Accuracy, 3 to 5000 psi

Viatran's Model 345 DigiComp pressure sensor is among our most accurate pressure transmitters for industrial test and research applications. The 345 measures gage and absolute pressure from 3 PSI to 5,000 PSI (0.2 to 345 bar) with standard accuracy of ≤±0.06% FSO.

0-7500 thru 100K psi, 4-20 mA output, 0.15% accuracy

Viatran's Model 345 High Range pressure sensor is among our most accurate pressure transmitters for industrial test and research applications at higher pressures. Improved accuracies are available, as well as improved temperature performance.

0-5 Vdc, 0-3 to 5000 psi

Designed for Overhead Junction Boxes

Model 422 is small in size, but packsa high-performance punch. The electronics and silicon sensor design have a combined accuracy of better than ±0.08%.

4-20 mA, 0-3 to 5000 psi

Designed for Overhead Junction Boxes

Model 423 is small in size, but packs a high-performance punch. The electronics and silicon sensor design have a combined accuracy of better than ±0.08%.

0-5 Vdc, 0-3 to 5000 psi

For use in applications requiring small footprint

Developed for engine test stands with space constraints, the Model 424 is small in size, but packs a high-performance punch. The electronics and silicon sensor design have a combined accuracy of better than ±0.08%.

Available standard output is 0-5 Vdc for PSIA or 0.25 - 5.25

Vdc for PSIG measurements.

4-20 mA, 0-100 psi thru 100K psi, Hazardous Approvals

570 provides a rugged, sealed solution for hazardous rated and harsh environments.

0-5 Vdc output, Hazardous Location Approvals, 0-100 thru 100K psi

770 uses a solid machined diaphragm sensor, which provides excellent durability and repeatability. 770 has both IS and Explosion Proof approvals, and can measure pressures up to 100K psi. A wide variety of wetted surface materials, process connections and electrical connections are available, and special wiring configurations are easily accommodated.

mv/V output, 0-100 thru 100K psi, Hazardous Location Approvals

870 employs a solid machined diaphragm sensor which provides a rugged and reliable solution with excellent repeatability and resistance to pressure spikes. 870 hazardous approval options include Intrinsically safe and Explosion proof for US, Canada and Atex.

HART® output, 0-100 thru 100K psi, Hazardous Location Approvals

Designed for applications including offshore oil rigs, oil production platforms, natural gas pipelines and rig safety systems, 970 uses a solid machined stainless steel diaphragm.

Sealed External Adjustment, Hazardous Approvals, 0-100 thru 100K psi

571 is Viatran's answer to the requirement for Hazardous Location approvals with external sealed adjustments. 571 is rangeable, offering the user flexibility if measuring different pressure levels.

mA output, 0-3 thru 0-5K psi, Hazardous Approvals

548 has the approvals necessary for use in hazardous areas. Viatran offers a variety of standard options and our ability to modify our products provides flexibility to meet your specific application needs.

mv/V output, Hazardous Location Approvals, 0-1.5 thru 5K psi

848 is a mv/V output, oil fill sensor with hazardous location approvals. In ranges from 1.5 to 5K, the 848 is available in Vacuum, Absolute and Gage formats to cover a broad spectrum of applications.

0-5 Vdc, Hazardous Location Approvals, 0-1.5 thru 5K PSI

748 has hazardous location approvals, optional zero and span adjustment and can measure pressures as low as 1.5 psi. Compound ranging, negative outputs, a variety of pressure and electrical connections are examples of options that are available to customize the 748 to your exact requirements

4-20 mA HART® Signal, Hazardous Location Approvals, 0-1.5 thru 5K psi

948 is Viatran's low pressure HART® transmitter with hazardous location approvals. Applications include fuel tank level, gas compressors, chemical processing.

0-5 Vdc output, 0-100 to 0-30K psi, Solid Machined Sensor

Viatran’s 24B is one of our most versatile pressure transducers for industrial applications. The 24B measures from 0-100 PSI to 0-30,000 PSI with standard linearity of ≤ ±0.25% FSO.

4-20 mA output, 0-100 to 0-30K psi, Solid Machined Sensor

Viatran’s 34B is one of our most versatile pressure transducers for industrial applications. The 34B measures from 0-100 PSI to 0-30,000 PSI with standard linearity of ≤ ±0.25% FSO.

Durable, dependable, accurate

Viatran’s “49” series is a robust, highly accurate pressure transmitter designed for the severe environments found in aerospace, engine test and fluid power control applications.

Durable, dependable, accurate

Viatran’s “49” series is a robust, highly accurate pressure transmitter designed for the severe environments found in aerospace, engine test and fluid power control applications.

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety. More information

Overview of Available Certificates and Approvals: Visit this link, which will take you to a page with a comprehensive list of current certificates and approvals for our products. Here, you can verify that our offerings meet the highest standards of quality and safety. More information

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results. More information

Discover the world of our online E-Learning page and find out how to streamline your daily use of our products. Our practical and comprehensive courses and informational materials will show you how to simplify and enhance the use of our technologies, uncover new information and techniques, and optimize work processes. With these resources, you'll achieve higher efficiency, save time, and improve your work results. More information

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support. More information

Our instructional videos offer an interactive way to learn about our products. Combining visual and auditory content, they provide practical solutions to common issues, saving you time and avoiding potential problems. If you encounter an issue, our video manuals offer detailed instructions and practical tips to help you resolve it. Available at any time, they provide a convenient resource that complements our technical support. More information

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support. More information

Our technical articles offer a practical way to learn more about our products and their use. They provide detailed information and practical tips on how to solve common problems, saving you time and helping you avoid potential issues. If you still encounter a problem, our technical articles offer specific instructions for solving it. They are available at any time and are a convenient source of information that complements our technical support. More information