Filtration systems and screencangers for industrial applications

Filtration is a process that separates or purifies substances. The mechanical separation processes of Maag filtration systems are physical. The principles are used in filters and screen converters for separating and cleaning plastic melts, chemicals and lubricants. They are also used in recycling, extrusion, rotational molding, in general in industrial applications and in the pharmaceutical and food industries.

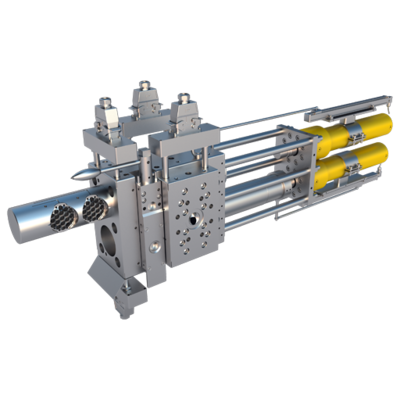

CSC/BF-4F

Automtic self cleaning screen changer for polymer extrusion industry and filtration systems

MAAG backflush automatic self cleaning screen changers are based on the proven double-piston design which operates without any mechanical seals. The screen changers are equipped with four screen cavities. This design is used mainly in recycling applications for filtration systems.

Multiple screen usage

Simple operation and uncomplicated control

High operational reliaility

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

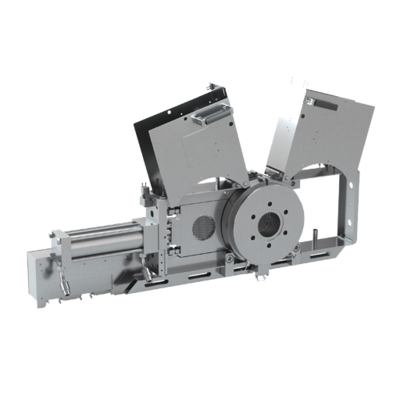

FSC-OEM

Optimized flat screen changer for processing of plastics

The flow optimized new version of MAAG´s FSC hydraulic and manual screen changers assist operators of plastic extrusion lines in achieving a reduced equipment footprint, reduced residence time and improved residence time distribution.

Reduction of pressure loss

Optimized flow

Increased production speed

Energy efficiency

Elimination of pressure fluctuations

Reduction of material consumption

Easy maintenance

multinex

Polymer filter candles and application for masterbatch and polymer filtration

MAAG multinex polymer filter candles are tailor-made for use in continuously operating dual bolt screen changers of the MAAG CSC-P/C series for polymer filtration.Compared to typical polymer application round screen plates, they increase the active screening area up to 60

Optimized for high viscosities

Reusable candle bodies

Economic perforated sleeve exchange

Screen mesh or metal fiber fleeze

Filter fineness 0.5-500 micron

micronex

Polymer application and polymer filtration with filter elements for large areas

MAAG offers high-quality polymer filter elements designed for long term use and multiple cleanings. MAAG can provide standard design polymer application or build to your requirements regarding:

Filter elements designed for individual processes

Optimized polymer flow

Maximized filter area

Lowest possible pressure loss

Designed to retain hard and deformable particles