MAAG Company

The MAAG Group comprises successful and renowned companies, each with their own impressive history. Automatik Plastics Machinery, Ettlinger Kunststoffmaschinen, Maag Pump Systems, Gala Industries, Reduction Engineering Scheer and Xantec Steuerungs- und EDV Technik are today the strong and innovative product brands of the MAAG Group.

The history of the MAAG Group thus begins in the late 19th century, with the establishment of Scheer as a metal foundry and machine factory in Stuttgart, Germany, in 1890. Maag Pump Systems was founded in 1913. Automatik Plastics Machinery was founded in 1947. Gala Industries was founded in 1959, and Ettlinger Kunststoffmaschinen in 1983. The youngest member of MAAG Group – Xantec Steuerungs- und EDV-Technik was founded in 1994. Over the decades, they have all grown into experts in the various fields of polymer production and processing.

All the members of the MAAG Group contribute their supreme expertise and years of experience in developing and manufacturing superb machines, plants, systems, and software – and will continue doing so in the future. The bundling of core competencies, industry best practices, the attentive maintenance of existing business relationships and creation of new ones, all provide the foundations for maximum customer satisfaction throughout the Group.

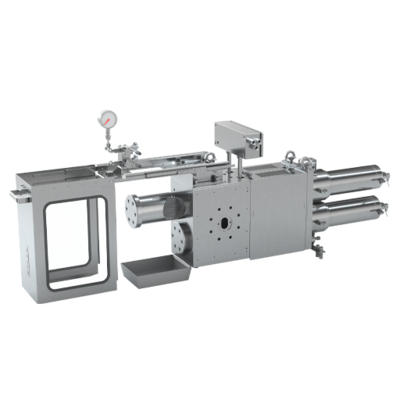

PRIMOPlus for pultruded LFT pellets

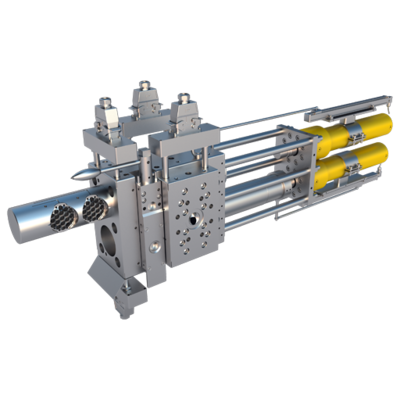

Dry cut pelletizing and strand pelletizing for all cases of application – PRIMOPlus for pultruded LFT pellets

The proven WSG dry-cut strand pelletizing systems with PRIMOPlus pelletizers produce the highest quality of cylindrical pellets particularly suitable for further application processing. Variable system configurations allow for optimal matching with your specific production requirements and also provide utmost flexibility in terms of product changeover for strand pelletizing and dry cut pelletizing.

Compact solution

Robust design

Feed roller with its own motor

Changes in the length and weight of pellets

Long life

Wear resistance

Easy access for cleaning

High Performance Melt Filter ECO

The continuous melt filters of the ECO series are mainly employed in PET and PA applications due to their special design and for filtering polymer feedstock from industrial waste with a low level of contamination or lightly contaminated post-consumer waste, as well as for clean virgin material. Our ECO melt filters are capable of processing a wide range of polymers. All solid or elastomer foreign particles such as gels, black specs, paper, wood, aluminum, copper, rubber, silicone or high-melting polymer composites are efficiently removed.

Continuous operation with a constant pressure on the outlet side

No need to replace the screen for several weeks, or possibly months, depending on the material and the applicationExtremely low melt losses

Absolutely clean filtration surface during the total time in operation

Up to 1.5% contaminants removed (we recommend our ERF filter for higher contaminant contents)

Completely closed system with no entrapped air

Short contaminant residence times in the filter

Consistent melt flow without dead zones or degraded polymer

Suitable for all polyolefins, polystyrenes, PET and PA

Better mixing and homogenizing of highly filled melts

High Performance Melt Filter ERF

The continuous melt filters in the ERF series are suitable for materials with up to 16% by weight contamination and are guaranteed to remain in use for long periods without changing the filter. Our ERF melt filters are capable of processing a wide range of polymers (e.g. LDPE, LLDPE, HDPE, PP, PS, ABS, PC / ABS, TPE, TPU, POM). All solid or elastomer foreign particles such as paper,wood, aluminum, copper, rubber, silicone, or high-melting polymer composites are efficiently removed.

Fully automatic, continuous operation

Up to 18% contaminants removed

Extremely low melt losses

More reliable processing due to constant pressure at the filter outlet

No need to replace the screen for several weeks, or possibly months, depending on the material and the application

Completely closed system with no entrapped air

Short contaminant residence times in the filter

Very simple replacement of the scraper from outside using a hydraulic cylinder

Elastomers (rubber, silicone) are efficiently filtered and discharged before they have a chance to be forced through the filter screen

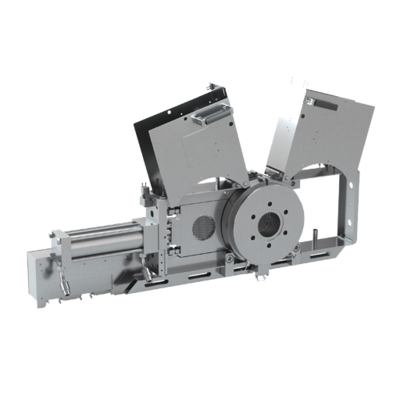

CSC/BF-4F

Automtic self cleaning screen changer for polymer extrusion industry and filtration systems

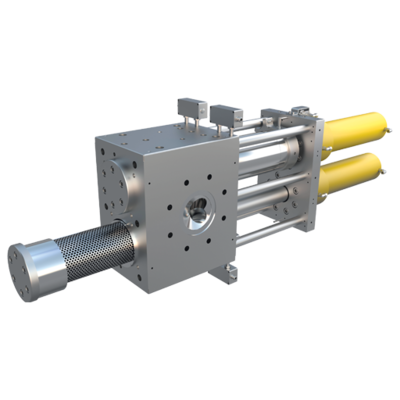

MAAG backflush automatic self cleaning screen changers are based on the proven double-piston design which operates without any mechanical seals. The screen changers are equipped with four screen cavities. This design is used mainly in recycling applications for filtration systems.

Multiple screen usage

Simple operation and uncomplicated control

High operational reliaility

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

CSC-R

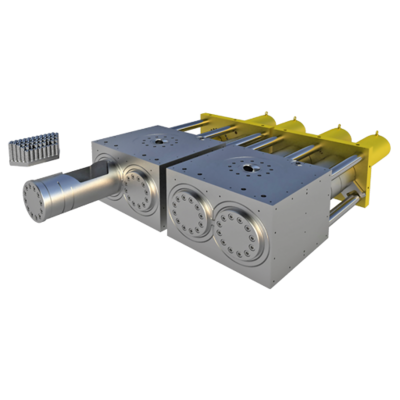

A Double pistion screenchanger for flitration systems

Large-area screen changers from MAAG are based on the sturdy and proven double-piston screen changer design. The patent-registered curved screen plate provides four times more active screen area than a conventional screen changer with circular screen cavities. The highly compact

Up to 4x more filter area than circular screen cavities

Higher throughput

Multiplied screen life time

Smaller hydraulic unit

Lower melt pressure

Higher filtration fineness

Reduced flux rate kg/h/cm2

Ultra-compact design

Less heating capacity

CSC-C

Screen changer with candle filter elements

MAAG’s CSC-C large scale screen changer with candle filter elements is the right choice if short melt residence time, small footprint and a simplified candle change are required.

Filter elements

Vertical / horizontal installation

2/4 pistons

Patented design

simplex

Discountinuous large area polymer filtration applications for industry and extrusion

MAAG-designed simplex polymer filter systems can be provided with either fixed or removable vessels. A compact preheat station with spare vessel is also available for locating near the polymer processing line for quick changeout. They are custom designed to minimize

Lower cost

Easier operation

No diverter valves

Less space requirements

Minimized pressure drop

Horizontal or vertical design

multinex

Polymer filter candles and application for masterbatch and polymer filtration

MAAG multinex polymer filter candles are tailor-made for use in continuously operating dual bolt screen changers of the MAAG CSC-P/C series for polymer filtration.Compared to typical polymer application round screen plates, they increase the active screening area up to 60

Optimized for high viscosities

Reusable candle bodies

Economic perforated sleeve exchange

Screen mesh or metal fiber fleeze

Filter fineness 0.5-500 micron

micronex

Polymer application and polymer filtration with filter elements for large areas

MAAG offers high-quality polymer filter elements designed for long term use and multiple cleanings. MAAG can provide standard design polymer application or build to your requirements regarding:

Filter elements designed for individual processes

Optimized polymer flow

Maximized filter area

Lowest possible pressure loss

Designed to retain hard and deformable particles

duplex

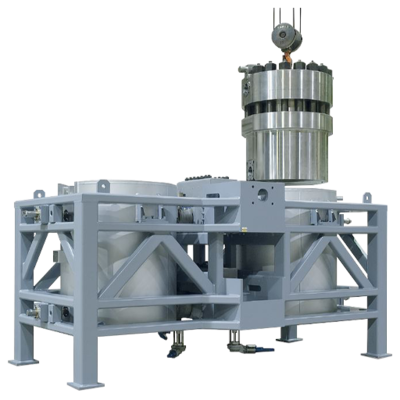

Polymer filter system´s for polymer filtration and continuous large area

MAAG’s duplex polymer filtration system was designed with considerable input from our customers. The result is a patented polymer filter system that offers process benefits such as minimized residence time and improved heat transfer efficiency.The combination of our modeling expertise

Reliable sealing

Improved venting

Better draining

Simplified vessel changeout

Improved accessibility

Safer operation

CSC

Continuous screen changer and double pistion screenchanger system for filtration - CSC

Continuous CSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration systems. Because of their constantly improved functionality, continuous screen changers from Maag increase product quality significantly. CSC screen changers

Simple operation and uncomplicated screen changing

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

FSC-OEM

Optimized flat screen changer for processing of plastics

The flow optimized new version of MAAG´s FSC hydraulic and manual screen changers assist operators of plastic extrusion lines in achieving a reduced equipment footprint, reduced residence time and improved residence time distribution.

Reduction of pressure loss

Optimized flow

Increased production speed

Energy efficiency

Elimination of pressure fluctuations

Reduction of material consumption

Easy maintenance