Quality control and analysis for pellets and color masterbatch

Measuring color as part of a quality control or quality assurance program is a complex topic, because these days, color consistency is an important component of product quality. High-quality products are therefore produced within extremely narrow color tolerances. As a result, color deviations can be quite expensive. Color corrections take a lot of time, reduce efficiency, and produce off-spec material, and are therefore unacceptably expensive. A complaint usually costs more than a complete color measuring system. In an era of quality management systems and certification in accordance with DIN, ISO, or other requirements and directives, a company can hardly afford not to check the color consistency of its dyed and lacquered plastic, glass, or powder products. The naked eye is often insufficient. An objective production-related measurement technology must be employed.

Extensive knowledge of production processes enables MAAG to develop innovative and pioneering solutions time and time again. The result of these developments is a carefully coordinated portfolio of machines and systems which is unique in its depth and breadth. We think the world could be more colorful!

COLOR CONTROL

Efficient process control and color measurement on the pellets

The COLOR CONTROL system was developed for online color measurement directly on the pellet and is one of the most modern online color measuring systems in the world.

Fast measurement: <2 minutes

Contactless measurement

Only 35 ml of measuring material

Bad ones are filtered out

Fast color correction

The extruder does not have to be stopped

Car quality monitoring

Mixing quality control

Automatic control

Inspection tool

Dosing unit control

Increases production capacity

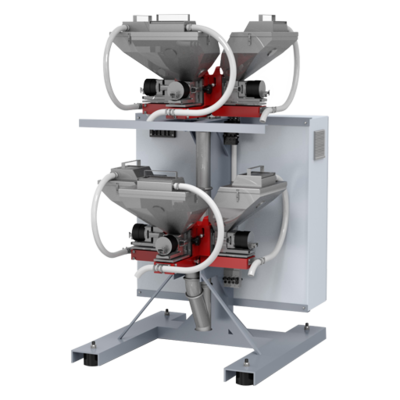

COLOR DOSING

Precise and quick dosing through optimal dosing precision and flexible and automatic process control

Precise dosing is a prerequisite for high-quality products. Complex color recipes in particular require trouble-free solutions during the dosing process. Optimum dosing precision and flexible and automated process control are decisive criteria – requirements that our dosing system meets. The system can be expanded modularly, and thus grows with the needs of plant operators.

Highly accurate measurement

Accurate reproducibility

Dosage of up to six ingredients

Dye change within 60 s

Robust and easy to clean

Easy retrofitting

Process automation

Integration into COLOR CONTROL

Guarantees higher quality

AUTO PELLET SAMPLER

Innovative pellet sampling unit for laboratory applications

The AUTO PELLET SAMPLER is designed for the lab or any other designated place where pellet samples from the production are needed. The fully automatic sampling system transports a container specially developed to collect pellets from the classifying sieve to the measuring device – overcoming several floors or distances of up to 300 m is no obstacle.

Compact design and flexible placement

Easy to use and automatic cleaning

Low maintenance

Automatic sample of up to 2 kg of pellets from several production lines

BATCH SAMPLER

Compact, fully automatic pellet sampling unit

Whether raw material or end product, modern industry often produces large quantities of bulk material. Regular analyses are required to ensure that pellets meet your quality standards. The BATCH SAMPLER is a compact, fully automatic system taking pellet samples by means of a suction lance at the end of the classifier.

Minimal maintenance

Flexible positioning

Automatic sampling 2 to 5 kg

Integrated gravimetric control

Integration into existing process management

Compactly built and flexible positioning, IP 55 protection

Plug and Play

One button control