extrex⁶ Y-Adaptor

The extrex⁶ Y-Adaptor unites two extrex x⁶ class gear pumps to ensure optimum efficiency and cost-effectiveness in extrusion systems. The extrex⁶ Y-Adaptor can be used with an extruder to feed two different die packs with a separate, constant melt stream each. Separate discharges from the individual gear wheel pairs are guaranteed thanks to the design and can be adjusted by changing the speed of the individually controlled drives. The extrex x⁶ class gear pump portfolio allows customers to choose between different thrust pieces to suit their application.

Product Quality6

Streamlined Linearity Elimination of incoming pulsations to maximize your product uniformity

Protected Polymer Minimized back-flow volume to speed up your polymer change Production Capability6

Endurance Shaft Improved load capability to raise your differential pressure

Peak Rate Superior flow capacity to boost your productivity Process Reliability6

Balanced Bearings

Unique self-centering shafts To maximize your process stability

maax PFC

The PFC automation system modular confi gurable solution for integrating melt pumps and

screen changer into complex extrusion process.

Operation, control, regulation and adjustment of the operating parameters. This guarantees optimum protection and operation of

the gear pump and screen changer. Process and operational reliability of the entire system is increased.

Simple and clear operation of the start-up and shutdown routines

Increased productivity, by saving recipes in parameter lists

Rapid and precise control of the extruder or pump speeds

Integrated temperature control of system components

Fast troubleshooting thanks to plain text messages

Scalable visualization of various operating parameters in a trend display

Viscoseal

ViscosealAvailable for high viscous fluids

The viscoseals are available for highly viscous fluids which are used for extrusion gear pump systems. The seal is contactless and dynamic. It has a simple design and has only one sealing part. A cooled model is available for the polymer extrusion industry is available and it is virtually maintenance free.

Support cart

Support cart - Support cart for multifunctional applications

Together with the extrex6 we can also provide the support cart as a package. The new multifunctional support cart can be mounted in 2 different directions and is also adjustable in the height.

Packing Glands

Packing glands in various executions for polymer gear pumps and chemical pumps. Without adaptions to modern sealing technology, these components are no longer widely used. Packing glands are available in a buffered model for polymer applications.

maax PC

The PC automation system is particularly suitable for stand alone or retrofitting of gear pumps in extrusion lines. Operation, control, regulation and monitoring of the operating parameters are simplified. Production data are displayed transparently and operation is simple and intuitive. Process and production safety of the line are increased.

Simple and clear operation of the start-up and shutdown routines

Quick and precise control of the extruder or pump speeds

Independent start-up and production control of the pump speed

Integrated temperature control of the line components

Fast troubleshooting thanks to plain text messages

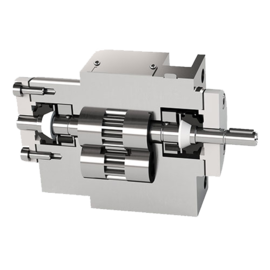

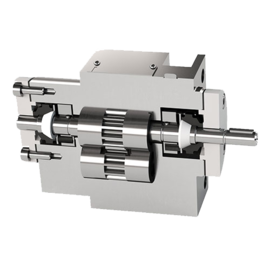

Drive units

Together with the extrex6 we can also provide the drive unit as a package. For optimum performance it is important the drive units are calculated to the application requirements and as accurately as possible. Maag has both the experts and high level modeling programs to assure just the right combination of torque, speed and efficiency.

Newly introduced is our Dual Drive unit designed for high abrasive, recycling and Fluoro polymer applications. The Dual drive unit is a Maag own development to bring up an economical and effective solution for processes requiring minimum gear toothand loading.

Calculated to your applications by expert with high level modeling capability

Complete service solution

Contact free operation of the gear pump

Longer lifetime of the gear pump

Blendrex®

Polymer processing, polymer systems, and polymer applications for extrusion in the polymer industry

MAAG specializes in the design and application of blendrex® heat exchangers used to preheat polystyrene melt prior to devolatilization and to cool polyester prior to spinning or pelletizing by polymer processing. blendrex® heat exchangers are problem solvers for many types of difficult heating and cooling polymer applications.

Significantly improve heat transfer rates of polymers and other viscous products. Three to seven times the rate obtainable compared to an “open tube” (no blendrex® elements) design

Provide a shorter product residence time inside the unit

blendrex® tube is a “plug flow” device

Tubes eliminate localized “hot spots”, and provides uniform temperature profile across the tube section

Contain alternating helical twist elements to obtain the high performance capabilities

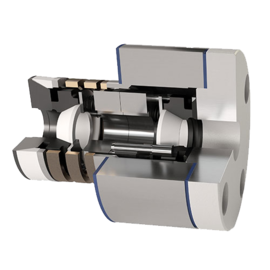

Double Mechanical Seal

Seal with buffer fluid for chemical pumps and chemical transfer pumps in industrial applications

The Double Mechanical Seal is a MAAG brand for industrial application and chemical pumps. It has a robust design with buffer fluid. Therefore, it is suitable for corrosive and abrasive applications. The sealing rings are available in carbon and SSiC (sintered silicon carbide ceramic) for chemical transfer pumps.

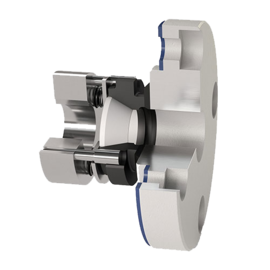

Single Mechanical Seal

Chemical pumps and chemical transfer pumps for abrasive fluids in industrial applications

This seal on the chemical transfer pump is applicable for high temperatures. A different material combination is available for aggressive and corrosive media. The sealing ring in SSiC can be used for abrasive fluids in industrial applications.

For corrosive fluids: Good fit

For abrasive fluids: Good fit (with SSiC)

TA-Luft certified: No

Double Mechanical Seal – balanced

Balanced seal for chemical pumps and chemical transfer pumps in industrial applications

The double mechanical seal with balanced sealing ring can be used for high inlet pressures. It needs to be used in combination with balanced shaft (double extended shaft, two seals) for chemical transfer pumps, chemical pumps, and other industrial applications.

Single Mechanical Seal – balanced

Balanced seal for chemical pumps and chemical transfer pumps

The single mechanical seal with balanced sealing ring can be used for high inlet pressures and needs to be used in combination with a balanced shaft (double extended shaft, two seals) for chemical pumps, chemical transfer pumps and industrial applications.

For corrosive fluids: Good fit

For abrasive fluids: Not suitable

TA-Luft certified: No