MAAG Company

The MAAG Group comprises successful and renowned companies, each with their own impressive history. Automatik Plastics Machinery, Ettlinger Kunststoffmaschinen, Maag Pump Systems, Gala Industries, Reduction Engineering Scheer and Xantec Steuerungs- und EDV Technik are today the strong and innovative product brands of the MAAG Group.

The history of the MAAG Group thus begins in the late 19th century, with the establishment of Scheer as a metal foundry and machine factory in Stuttgart, Germany, in 1890. Maag Pump Systems was founded in 1913. Automatik Plastics Machinery was founded in 1947. Gala Industries was founded in 1959, and Ettlinger Kunststoffmaschinen in 1983. The youngest member of MAAG Group – Xantec Steuerungs- und EDV-Technik was founded in 1994. Over the decades, they have all grown into experts in the various fields of polymer production and processing.

All the members of the MAAG Group contribute their supreme expertise and years of experience in developing and manufacturing superb machines, plants, systems, and software – and will continue doing so in the future. The bundling of core competencies, industry best practices, the attentive maintenance of existing business relationships and creation of new ones, all provide the foundations for maximum customer satisfaction throughout the Group.

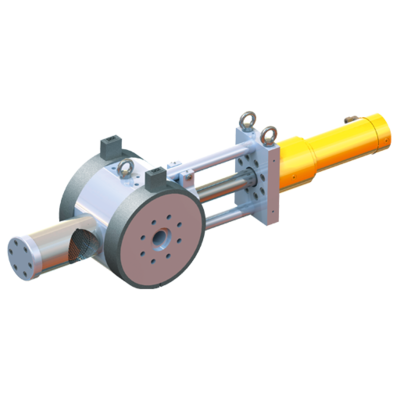

FSC - Hydraulic plate screen changer for filtration systems and polymer production

FSC screen changers from Maag are equipped with a pressure-adaptive sealing system as a standard. Thanks to this sealing system, the required sealing forces are adjusted to the actual melt pressure automatically. The narrow design is especially suited for being used in applications with thermally sensitive materials. Their solid and robust construction, available in all sizes and designs, ensures a reliable and leakfree filtration of molten polymers for many years. The hydraulically operated screen changer reliably guarantees the protection of melt pumps and mold gaps from damage and dirt.

Suitable for Compounding, Recycling, Extrusion, Masterbatch

Simple operation and uncomplicated screen changing

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

SSC

Effective single piston screen changer for reliable melt cost effective filtration solution

The compact single-piston screen changers SSC from MAAG provide a cost-effective filtration alternative for extrusion applications which allow for interruptions in the melt stream during screen changeovers. SSC operate without any additional seal.

Simple operation and uncomplicated screen changing

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

DSC - Single piston screen changer for extrusion and compounding applications

Discontinuous DSC screen changers from MAAG with their robust and leak-free operation meet highest quality standards with respect to melt filtration. Due to their constantly improved functionality continuous screen changers from Maag increase product quality significantly. DSC screen changers are based on the proven single-piston design that operates without any additional seals. Their sturdy construction available in all sizes and designs guarantees a reliable and leak-free filtration of polymer melts for many years.

Suitable for Masterbatch, Compounding, Recycling, Extrusion, Hot Melt Adhesives

Simple operation and uncomplicated screen changing

High operational reliability

Short material residence time

Leak-free mode of operation

Low pressure consumption

Flow channel geometry without any dead spots

Extrex-Y adapter

Twin outlet gear pump for complex extrusion applications

The extrex⁶ Y-Adaptor unites two extrex x⁶ class gear pumps to ensure optimum efficiency and cost-effectiveness in extrusion systems.

Multilayer films

Improved output consistency

Larger range of applications

Short delays

Compact design

Self-cleaning properties

Extrex⁶ MP

Extrusion operations require extremely reliable gear pump systems with high output consistency and a confi guration to suit each application.

The modular design of extrex® gear pumps easily meets the requirements for these

diverse applications.

The extrex⁶ MP is a high pressure gear pump for the most demanding thermoplastic applications. With the new x⁶ class design you have additional benefi ts compared to the classic gear pump designs.

The flange design ST is already the same as the classic trudex, so there is no need to change process connections when replacing classic trudex pumps.

Suitable for Extrusion

Operation in the high-pressure range up to 700 bar

High overall level of efficiency due to cutting-edge gear and slide bearing technology

Flexible use due to simple retro-fitting

Robust and compact construction

Low-pulsation conveying even at high-pressure differentials

Thermorex⁶ TR/TB/TP/TO

Polymer processes require pumps that gently process both high and low viscosity plastic melt through the system.

Specially designed low-compression teeth allow the thermorex®-x⁶ class transfer, booster or metering gear pump to achieve both high pressure and low shear. The plastic melt is conveyed with a constant, precise flow even at high discharge pressures — and this also for low viscosity products like prepolymers, where former pump generations reached their limits. Additionally, their high efficiency and long service life will enhance the capacity of any given production plant.

Suitable for Resin & Virgin Polymer Production

+ 25 % more wear resistant

- 12 % less energy consumption

+ 10 % better vol. efficiency

- 40 % less temperature increase

+ 30 % better heat transfer in the bearings

- 50 % less pulsation

Extrex⁶ EP

The extrex6 EP gear pump is an intermediate pressure solution for applications requiring higher pressure, greater load bearing considerations for low lubricity products. With the new x6 class design you have additional benefits compared to the classic gear pump designs.

Suitable for Extrusion

Operation in the high-pressure range up to 700 bar

High overall level of efficiency due to cutting-edge gear and slide bearing technology

Flexible use due to simple retro-fitting

Robust and compact construction

Low-pulsation conveying even at high-pressure differentials

extrex⁶ SP

The extrex⁶ SP gear pump is a high pressure gear pump for applications dictating high pressures and loads. With the new x⁶ class design you have additional benefits compared to the classic gear pump designs.

All Pumps are available with ST design (flow optimized) and with the 5R design (Retrofit flange design classic pump).

Extrusion operations require extremely reliable gear pump systems with high output consistency and a configuration to suit each application. The modular design of extrex® gear pumps easily meets the requirements for these diverse applications.

Suitable for Extrusion

Operation in the high-pressure range up to 700 bar

High overall level of efficiency due to cutting-edge gear and slide bearing technology

Flexible use due to simple retro-fitting

Robust and compact construction

Low-pulsation conveying even at high-pressure differentials

Extrex⁶ GU

Extrusion operations require extremely reliable gear pump systems with high output consistency and a configuration to suit each application.

The modular design of extrex® gear pumps easily meets the requirements for these diverse applications.

The extrex⁶ GU gear pump is a general use design that elevates your process to the next level. With the new x⁶ class design you have additional benefi ts compared to the classic gear pump designs.

All pumps are available with ST design (flow optimized) and with the 5R design (Retrofit flange design classic pump).

Suitable for Masterbatch, Compounding, Recycling, Extrusion

Operation in the high-pressure range up to 700 bar

High overall level of efficiency due to cutting-edge gear and slide bearing technology

Flexible use due to simple retro-fitting

Robust and compact construction

Low-pulsation conveying even at high-pressure differentials